Countersunk Magnets- Neodymium Cup Magnets with 90°Mounting Hole

Countersunk Magnets, also known as Round Base, Round Cup, Cup or RB magnets, are powerful mounting magnets, built with neodymium magnets in a steel cup with a 90°countersunk hole on the working surface to accommodate a standard flat-head screw. The screw head sits flush or slightly below the surface when affixed to your product.

The magnetic holding is focused on the working surface and is significantly stronger than an individual magnet. The non-working surface is very little or no magnetic force.

Constructed with N35 Neodymium magnets encased in a steel cup, plated with a triple-layer of Nickel-Copper-Nickel (Ni-Cu-Ni) for maximum protection against corrosion & oxidation.

Neodymium cup magnets are used for any application where high-magnetic strength is required. They are ideal for lifting, holding & positioning, and mounting applications for indicators, lights, lamps, antennas, inspection equipment, furniture repair, gate latches, closing mechanisms, machinery, vehicles&more.

Countersunk Magnets

Countersunk magnets are an extremely popular fixing method due to their ease of application, clean aesthetic and strong performance. These magnets are easily fixed in place with screws and are used for discreet door and drawer closures and for signage and displays.

The Countersunk hole magnets in this category have one or two holes with countersunk, so that the block magnets can be screwed on using countersunk screws. Due to the flat design, the magnets are barely bulky and still have a good adhesive force, which you are used to, with neodymium magnets. The magnets are magnetized by the height (axial magnetization).Of course there are a large number of possible uses for this magnet variant, for example: Trade fairs and shop construction, kitchen or furniture construction and many more. You can also use it to attach signs, tools and metallic objects so that they are rock solid.

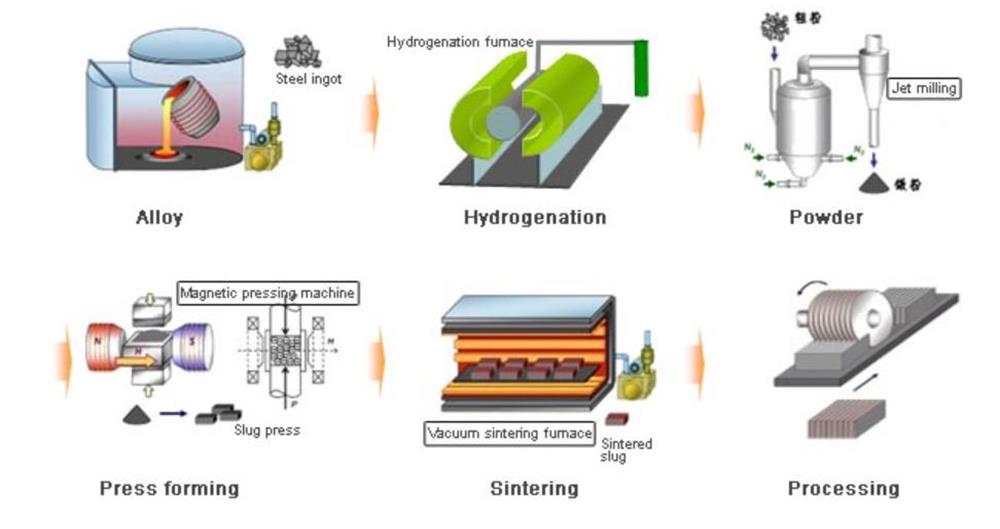

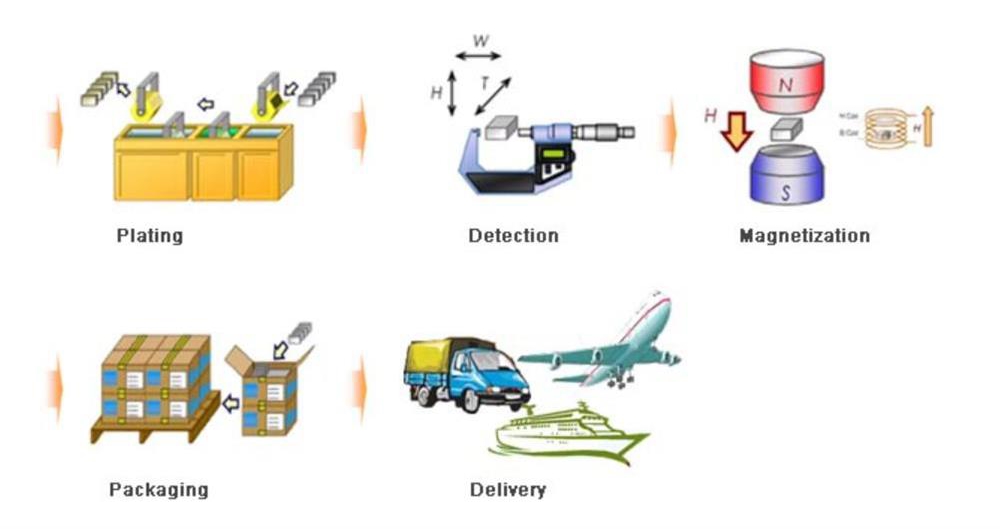

Process Flow Diagram