Chinese wholesale Strong Permanent Neodymium Magnets - Strong Permanent Neodymium Magnets – Pulong Detail:

Product Description

Composite: Rare Earth Magnets

Size: Customized for Neodymium Magnet

Other Coating: Ni, Ni-Cu-Ni, Zn(Cr3+), Tin, Epoxy, Ni-AG, Ni-Au

Tolerance: +/-0.05 for Neodymium Magnet

Delivery Detail: 15 Days After Order Confirmed for Neodymium Magnet

Export Markets: Global

OEM Service: Yes

Other Shape: Arc, Ring, Ball, Bar, Strick, Sheet, Block for Neo

Transport Package: Sea Pallet / Air Carton / Express Packaging

Origin: China

Production Capacity: 10, 000, 000 PCS/Month

Magnetic Properties

| Grade | Remanence | Magnetic Inductio | Intrinsic Coercivity | Max Magnetic Energy Product | Temperature Coefficient | Max Working Temperture | Density | |||||

| Br | Hcb | Hcj | (BH)max | α Br | β Hcj | Tw | ρ | |||||

| T | kGs | kA/m | kOe | kA/m | kOe | KJ/m3 | MGOe | %/℃ | %/℃ | ℃ | g/cm2 | |

| N55 | ≥1.45 | ≥14.5 | 836 | 10.5 | ≥955 | ≥12 | 406-437 | 51-55 | -0.12 | -0.8 | 80 | ≥7.5 |

| N54 | ≥1.44 | ≥14.4 | 836 | 10.5 | ≥955 | ≥12 | 398-437 | 50-55 | -0.12 | -0.8 | 80 | ≥7.5 |

| N52 | 1.42-1.44 | 14.2-14.4 | 836 | 10.5 | ≥955 | ≥12 | 390-422 | 49-53 | -0.12 | -0.8 | 80 | ≥7.5 |

| N50 | 1.4-1.42 | 14-14.2 | 836 | 10.5 | ≥955 | ≥12 | 374-406 | 47-51 | -0.12 | -0.8 | 80 | ≥7.5 |

| N48 | 1.37-1.4 | 13.7-14 | 915 | 11.5 | ≥955 | ≥12 | 366-390 | 46-49 | -0.12 | -0.8 | 80 | ≥7.5 |

| N45 | 1.32-1.37 | 13.2-13.7 | 915 | 11.5 | ≥955 | ≥12 | 342-366 | 43-46 | -0.12 | -0.8 | 80 | ≥7.5 |

| 54M | ≥1.44 | ≥14.4 | 1056 | 13.3 | ≥1114 | ≥14 | 398-422 | 50-53 | -0.12 | -0.8 | 100 | ≥7.5 |

| 52M | 1.42-1.44 | 14.2-14.4 | 1056 | 13.3 | ≥1114 | ≥14 | 390-422 | 49-53 | -0.12 | -0.8 | 100 | ≥7.5 |

| 50M | 1.4-1.42 | 14-14.2 | 1034 | 13.0 | ≥1114 | ≥14 | 374-406 | 47-51 | -0.12 | -0.8 | 100 | ≥7.5 |

| 48M | 1.37-1.4 | 13.7-14 | 1019 | 12.8 | ≥1114 | ≥14 | 366-390 | 46-49 | -0.12 | -0.8 | 100 | ≥7.5 |

| 45M | 1.32-1.37 | 13.2-13.7 | 1008 | 12.7 | ≥1114 | ≥14 | 342-366 | 43-46 | -0.12 | -0.8 | 100 | ≥7.5 |

| 42M | 1.28-1.32 | 12.8-13.2 | 970 | 12.2 | ≥1114 | ≥14 | 318-342 | 40-43 | -0.12 | -0.8 | 100 | ≥7.5 |

| 54H | ≥1.44 | ≥14.4 | 1056 | 13.3 | ≥1353 | ≥17 | 398-422 | 50-53 | -0.12 | -0.7 | 120 | ≥7.5 |

| 52H | 1.42-1.44 | 14.2-14.4 | 1056 | 13.3 | ≥1353 | ≥17 | 390-422 | 49-53 | -0.12 | -0.7 | 120 | ≥7.5 |

| 50H | 1.4-1.42 | 14-14.2 | 1034 | 13.0 | ≥1353 | ≥17 | 374-406 | 47-51 | -0.12 | -0.7 | 120 | ≥7.5 |

| 48H | 1.37-1.4 | 13.7-14 | 1019 | 12.8 | ≥1353 | ≥17 | 366-390 | 46-49 | -0.12 | -0.7 | 120 | ≥7.5 |

| 45H | 1.32-1.37 | 13.2-13.7 | 1008 | 12.7 | ≥1353 | ≥17 | 342-366 | 43-46 | -0.12 | -0.7 | 120 | ≥7.5 |

| 42H | 1.28-1.32 | 12.8-13.2 | 970 | 12.2 | ≥1353 | ≥17 | 318-342 | 40-43 | -0.12 | -0.7 | 120 | ≥7.5 |

| 40H | 1.26-1.28 | 12.6-12.8 | 948 | 11.9 | ≥1353 | ≥17 | 302-326 | 38-41 | -0.12 | -0.7 | 120 | ≥7.5 |

| 52SH | 1.42-1.44 | 14.2-14.4 | 1056 | 13.3 | ≥1592 | ≥20 | 390-422 | 49-53 | -0.12 | -0.6 | 150 | ≥7.5 |

| 50SH | 1.4-1.42 | 14-14.2 | 1034 | 13.0 | ≥1592 | ≥20 | 374-406 | 47-51 | -0.12 | -0.6 | 150 | ≥7.5 |

| 48SH | 1.37-1.4 | 13.7-14 | 1019 | 12.8 | ≥1592 | ≥20 | 366-390 | 46-49 | -0.12 | -0.6 | 150 | ≥7.5 |

| 45SH | 1.32-1.37 | 13.2-13.7 | 1008 | 12.7 | ≥1592 | ≥20 | 342-366 | 43-46 | -0.12 | -0.6 | 150 | ≥7.5 |

| 42SH | 1.28-1.32 | 12.8-13.2 | 970 | 12.2 | ≥1592 | ≥20 | 318-342 | 40-43 | -0.12 | -0.6 | 150 | ≥7.5 |

| 40SH | 1.26-1.28 | 12.6-12.8 | 948 | 11.9 | ≥1592 | ≥20 | 302-326 | 38-41 | -0.12 | -0.6 | 150 | ≥7.5 |

| 38SH | 1.22-1.26 | 12.2-12.6 | 925 | 11.6 | ≥1592 | ≥20 | 287-310 | 36-39 | -0.12 | -0.6 | 150 | ≥7.5 |

| 35SH | 1.17-1.22 | 11.7-12.2 | 887 | 11.1 | ≥1592 | ≥20 | 263-287 | 33-36 | -0.12 | -0.6 | 150 | ≥7.5 |

| 33SH | 1.13-1.17 | 11.3-11.7 | 857 | 10.8 | ≥1592 | ≥20 | 247-271 | 31-34 | -0.12 | -0.6 | 150 | ≥7.5 |

| 30SH | 1.08-1.13 | 10.8-11.3 | 819 | 10.3 | ≥1592 | ≥20 | 223-254 | 28-32 | -0.12 | -0.6 | 150 | ≥7.5 |

| 48UH | 1.36-1.4 | 13.6-14 | 1029 | 12.9 | ≥1990 | ≥25 | 366-390 | 46-49 | -0.12 | -0.6 | 180 | ≥7.5 |

| 45UH | 1.32-1.37 | 13.2-13.7 | 1008 | 12.7 | ≥1990 | ≥25 | 342-366 | 43-46 | -0.12 | -0.6 | 180 | ≥7.5 |

| 42UH | 1.28-1.32 | 12.8-13.2 | 970 | 12.2 | ≥1990 | ≥25 | 318-342 | 40-43 | -0.12 | -0.6 | 180 | ≥7.5 |

| 40UH | 1.26-1.28 | 12.6-12.8 | 948 | 11.9 | ≥1990 | ≥25 | 302-326 | 38-41 | -0.12 | -0.6 | 180 | ≥7.5 |

| 38UH | 1.22-1.26 | 12.2-12.6 | 925 | 11.6 | ≥1990 | ≥25 | 287-310 | 36-39 | -0.12 | -0.6 | 180 | ≥7.5 |

| 35UH | 1.17-1.22 | 11.7-12.2 | 887 | 11.1 | ≥1990 | ≥25 | 263-287 | 33-36 | -0.12 | -0.6 | 180 | ≥7.5 |

| 33UH | 1.13-1.17 | 11.3-11.7 | 857 | 10.8 | ≥1990 | ≥25 | 247-271 | 31-34 | -0.12 | -0.6 | 180 | ≥7.5 |

| 30UH | 1.08-1.13 | 10.8-11.3 | 819 | 10.3 | ≥1990 | ≥25 | 223-255 | 28-32 | -0.12 | -0.51 | 180 | ≥7.5 |

| 28UH | 1.02-1.08 | 10.2-10.8 | 773 | 9.7 | ≥1990 | ≥25 | 207-231 | 26-29 | -0.12 | -0.51 | 180 | ≥7.5 |

| 42EH | 1.28-1.32 | 12.8-13.2 | 970 | 12.2 | ≥2388 | ≥30 | 318-342 | 40-43 | -0.12 | -0.5 | 200 | ≥7.5 |

| 40EH | 1.25-1.28 | 12.5-12.8 | 948 | 11.9 | ≥2388 | ≥30 | 302-326 | 38-41 | -0.12 | -0.5 | 200 | ≥7.5 |

| 38EH | 1.22-1.26 | 12.2-12.6 | 925 | 11.6 | ≥2388 | ≥30 | 287-310 | 36-39 | -0.12 | -0.5 | 200 | ≥7.5 |

| 35EH | 1.17-1.22 | 11.7-12.2 | 887 | 11.1 | ≥2388 | ≥30 | 263-287 | 33-36 | -0.12 | -0.5 | 200 | ≥7.5 |

| 33EH | 1.13-1.17 | 11.3-11.7 | 857 | 10.8 | ≥2388 | ≥30 | 247-271 | 31-34 | -0.12 | -0.5 | 200 | ≥7.5 |

| 30EH | 1.08-1.13 | 10.8-11.3 | 819 | 10.3 | ≥2388 | ≥30 | 223-255 | 28-32 | -0.12 | -0.51 | 200 | ≥7.5 |

| 28EH | 1.02-1.08 | 10.2-10.8 | 773 | 9.7 | ≥2388 | ≥30 | 207-231 | 26-29 | -0.12 | -0.51 | 200 | ≥7.5 |

| 40AH | 1.25-1.28 | 12.5-12.8 | 948 | 11.9 | ≥2786 | ≥35 | 302-326 | 38-41 | -0.12 | -0.51 | 220 | ≥7.5 |

| 38AH | 1.22-1.26 | 12.2-12.6 | 925 | 11.6 | ≥2786 | ≥35 | 287-310 | 36-39 | -0.12 | -0.51 | 220 | ≥7.5 |

| 35AH | 1.17-1.22 | 11.7-12.2 | 887 | 11.1 | ≥2786 | ≥35 | 263-287 | 33-36 | -0.12 | -0.51 | 220 | ≥7.5 |

| 33AH | 1.13-1.17 | 11.3-11.7 | 857 | 10.8 | ≥2786 | ≥35 | 247-271 | 31-34 | -0.12 | -0.51 | 220 | ≥7.5 |

| 30AH | 1.08-1.13 | 10.8-11.3 | 819 | 10.3 | ≥2786 | ≥35 | 223-255 | 28-32 | -0.12 | -0.51 | 220 | ≥7.5 |

| 28AH | 1.02-1.08 | 10.2-10.8 | 773 | 9.7 | ≥2786 | ≥35 | 199-231 | 25-29 | -0.12 | -0.51 | 220 | ≥7.5 |

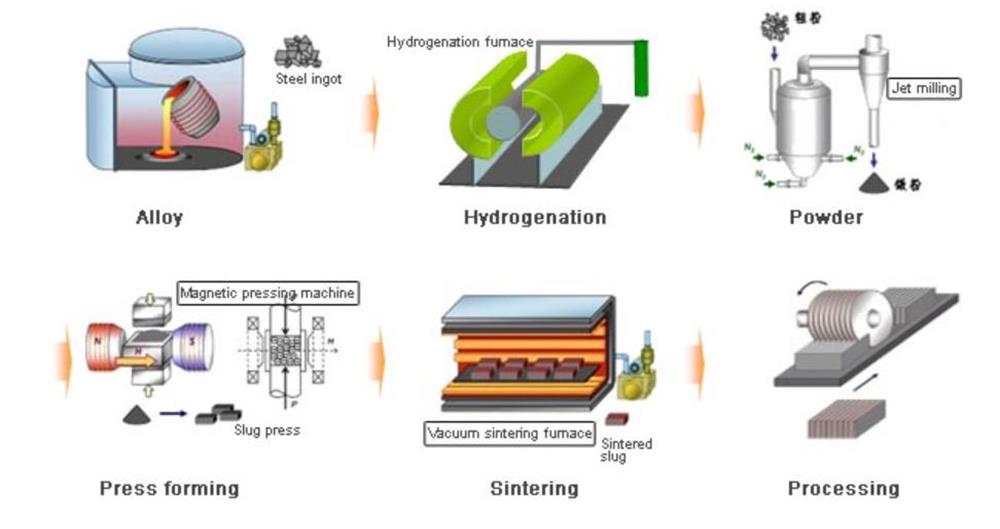

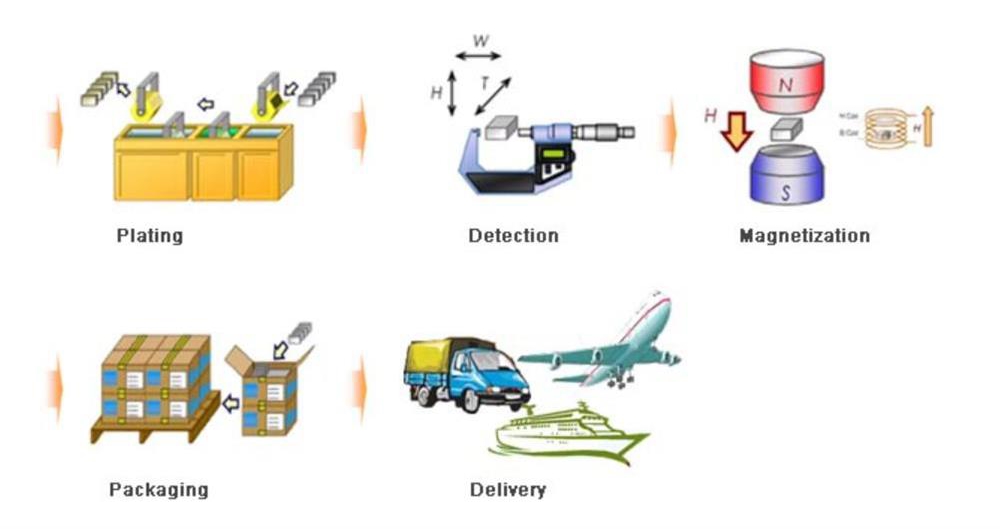

Process Flow Diagram

Dimensional Tolerance

| Squared-shaped products | |||

| Dimensional Range | Dimensional Tolerance | Parallellism | Rectangularity |

| 0.5≤L≤10 | ±0.03 | ±0.03 | <0.3 |

| 10≤L≤50 | ±0.05 | ±0.05 | |

| L>50 | ±0.1 | ±0.1 | |

| Wafer-shaped Products | |||

| Dimensional Range | Circularity | Dimensional Tolerance | Planeness |

| 1≤D≤5 | ±0.02 | ±0.02 | ±0.02 |

| 5≤D≤25 | ±0.03 | ±0.05 | ±0.02 |

| 25≤D≤50 | ±0.05 | ±0.05 | ±0.03 |

| D>50 | ±0.05 | ±0.1 | ±0.1 |

| Ring-shaped Products | |||

| Dimensional Range | Circularity | Dimensional Tolerance | Planeness |

| 1≤d≤3 | ±0.02 | ±0.02 | ±0.02 |

| 3≤d≤5 | ±0.04 | ±0.03 | ±0.02 |

| 5≤d≤15 | ±0.05 | ±0.05 | ±0.03 |

| d>15 | ±0.1 | ±0.05 | ±0.1 |

| Segment-shaped Products | ||

| Geometric Tolerance | Dimensional Range | Dimensional Tolerance |

| Wall Thickness | T≤10 | ±0.04 |

| 10<T≤25 | ±0.05 | |

| Length | L≤10 | ±0.03 |

| 10<L≤25 | ±0.03 | |

| 25<L≤63 | ±0.04 | |

| L>63 | ±0.06 | |

| Chord Length | W≤63 | ±0.05 |

| W>63 | ±0.06 | |

Pulong Magnet has more than 10 years’ experience to deal with the magnets and magnetic products!

Strategic cooperation with China’s No.1 rare earth miner Chinalco!

Contact us today or send us a special request and let us know what you are looking for.

Product detail pictures:

Related Product Guide:

Our corporation has been specializing in brand strategy. Customers' gratification is our greatest advertising. We also source OEM company for Chinese wholesale Strong Permanent Neodymium Magnets - Strong Permanent Neodymium Magnets – Pulong, The product will supply to all over the world, such as: Orlando, Denver, Naples, We guarantee that our company will try our best to reduce customer purchase cost , shorten the period of purchase , stable products quality , increase customers' satisfaction and achieve win-win situation .

This company can be well to meet our needs on product quantity and delivery time, so we always choose them when we have procurement requirements.