Low MOQ for Strong Magnet Hooks - Strong Permanent Neodymium Magnets – Pulong Detail:

Product Description

Composite: Rare Earth Magnets

Size: Customized for Neodymium Magnet

Other Coating: Ni, Ni-Cu-Ni, Zn(Cr3+), Tin, Epoxy, Ni-AG, Ni-Au

Tolerance: +/-0.05 for Neodymium Magnet

Delivery Detail: 15 Days After Order Confirmed for Neodymium Magnet

Export Markets: Global

OEM Service: Yes

Other Shape: Arc, Ring, Ball, Bar, Strick, Sheet, Block for Neo

Transport Package: Sea Pallet / Air Carton / Express Packaging

Origin: China

Production Capacity: 10, 000, 000 PCS/Month

Magnetic Properties

| Grade | Remanence | Magnetic Inductio | Intrinsic Coercivity | Max Magnetic Energy Product | Temperature Coefficient | Max Working Temperture | Density | |||||

| Br | Hcb | Hcj | (BH)max | α Br | β Hcj | Tw | ρ | |||||

| T | kGs | kA/m | kOe | kA/m | kOe | KJ/m3 | MGOe | %/℃ | %/℃ | ℃ | g/cm2 | |

| N55 | ≥1.45 | ≥14.5 | 836 | 10.5 | ≥955 | ≥12 | 406-437 | 51-55 | -0.12 | -0.8 | 80 | ≥7.5 |

| N54 | ≥1.44 | ≥14.4 | 836 | 10.5 | ≥955 | ≥12 | 398-437 | 50-55 | -0.12 | -0.8 | 80 | ≥7.5 |

| N52 | 1.42-1.44 | 14.2-14.4 | 836 | 10.5 | ≥955 | ≥12 | 390-422 | 49-53 | -0.12 | -0.8 | 80 | ≥7.5 |

| N50 | 1.4-1.42 | 14-14.2 | 836 | 10.5 | ≥955 | ≥12 | 374-406 | 47-51 | -0.12 | -0.8 | 80 | ≥7.5 |

| N48 | 1.37-1.4 | 13.7-14 | 915 | 11.5 | ≥955 | ≥12 | 366-390 | 46-49 | -0.12 | -0.8 | 80 | ≥7.5 |

| N45 | 1.32-1.37 | 13.2-13.7 | 915 | 11.5 | ≥955 | ≥12 | 342-366 | 43-46 | -0.12 | -0.8 | 80 | ≥7.5 |

| 54M | ≥1.44 | ≥14.4 | 1056 | 13.3 | ≥1114 | ≥14 | 398-422 | 50-53 | -0.12 | -0.8 | 100 | ≥7.5 |

| 52M | 1.42-1.44 | 14.2-14.4 | 1056 | 13.3 | ≥1114 | ≥14 | 390-422 | 49-53 | -0.12 | -0.8 | 100 | ≥7.5 |

| 50M | 1.4-1.42 | 14-14.2 | 1034 | 13.0 | ≥1114 | ≥14 | 374-406 | 47-51 | -0.12 | -0.8 | 100 | ≥7.5 |

| 48M | 1.37-1.4 | 13.7-14 | 1019 | 12.8 | ≥1114 | ≥14 | 366-390 | 46-49 | -0.12 | -0.8 | 100 | ≥7.5 |

| 45M | 1.32-1.37 | 13.2-13.7 | 1008 | 12.7 | ≥1114 | ≥14 | 342-366 | 43-46 | -0.12 | -0.8 | 100 | ≥7.5 |

| 42M | 1.28-1.32 | 12.8-13.2 | 970 | 12.2 | ≥1114 | ≥14 | 318-342 | 40-43 | -0.12 | -0.8 | 100 | ≥7.5 |

| 54H | ≥1.44 | ≥14.4 | 1056 | 13.3 | ≥1353 | ≥17 | 398-422 | 50-53 | -0.12 | -0.7 | 120 | ≥7.5 |

| 52H | 1.42-1.44 | 14.2-14.4 | 1056 | 13.3 | ≥1353 | ≥17 | 390-422 | 49-53 | -0.12 | -0.7 | 120 | ≥7.5 |

| 50H | 1.4-1.42 | 14-14.2 | 1034 | 13.0 | ≥1353 | ≥17 | 374-406 | 47-51 | -0.12 | -0.7 | 120 | ≥7.5 |

| 48H | 1.37-1.4 | 13.7-14 | 1019 | 12.8 | ≥1353 | ≥17 | 366-390 | 46-49 | -0.12 | -0.7 | 120 | ≥7.5 |

| 45H | 1.32-1.37 | 13.2-13.7 | 1008 | 12.7 | ≥1353 | ≥17 | 342-366 | 43-46 | -0.12 | -0.7 | 120 | ≥7.5 |

| 42H | 1.28-1.32 | 12.8-13.2 | 970 | 12.2 | ≥1353 | ≥17 | 318-342 | 40-43 | -0.12 | -0.7 | 120 | ≥7.5 |

| 40H | 1.26-1.28 | 12.6-12.8 | 948 | 11.9 | ≥1353 | ≥17 | 302-326 | 38-41 | -0.12 | -0.7 | 120 | ≥7.5 |

| 52SH | 1.42-1.44 | 14.2-14.4 | 1056 | 13.3 | ≥1592 | ≥20 | 390-422 | 49-53 | -0.12 | -0.6 | 150 | ≥7.5 |

| 50SH | 1.4-1.42 | 14-14.2 | 1034 | 13.0 | ≥1592 | ≥20 | 374-406 | 47-51 | -0.12 | -0.6 | 150 | ≥7.5 |

| 48SH | 1.37-1.4 | 13.7-14 | 1019 | 12.8 | ≥1592 | ≥20 | 366-390 | 46-49 | -0.12 | -0.6 | 150 | ≥7.5 |

| 45SH | 1.32-1.37 | 13.2-13.7 | 1008 | 12.7 | ≥1592 | ≥20 | 342-366 | 43-46 | -0.12 | -0.6 | 150 | ≥7.5 |

| 42SH | 1.28-1.32 | 12.8-13.2 | 970 | 12.2 | ≥1592 | ≥20 | 318-342 | 40-43 | -0.12 | -0.6 | 150 | ≥7.5 |

| 40SH | 1.26-1.28 | 12.6-12.8 | 948 | 11.9 | ≥1592 | ≥20 | 302-326 | 38-41 | -0.12 | -0.6 | 150 | ≥7.5 |

| 38SH | 1.22-1.26 | 12.2-12.6 | 925 | 11.6 | ≥1592 | ≥20 | 287-310 | 36-39 | -0.12 | -0.6 | 150 | ≥7.5 |

| 35SH | 1.17-1.22 | 11.7-12.2 | 887 | 11.1 | ≥1592 | ≥20 | 263-287 | 33-36 | -0.12 | -0.6 | 150 | ≥7.5 |

| 33SH | 1.13-1.17 | 11.3-11.7 | 857 | 10.8 | ≥1592 | ≥20 | 247-271 | 31-34 | -0.12 | -0.6 | 150 | ≥7.5 |

| 30SH | 1.08-1.13 | 10.8-11.3 | 819 | 10.3 | ≥1592 | ≥20 | 223-254 | 28-32 | -0.12 | -0.6 | 150 | ≥7.5 |

| 48UH | 1.36-1.4 | 13.6-14 | 1029 | 12.9 | ≥1990 | ≥25 | 366-390 | 46-49 | -0.12 | -0.6 | 180 | ≥7.5 |

| 45UH | 1.32-1.37 | 13.2-13.7 | 1008 | 12.7 | ≥1990 | ≥25 | 342-366 | 43-46 | -0.12 | -0.6 | 180 | ≥7.5 |

| 42UH | 1.28-1.32 | 12.8-13.2 | 970 | 12.2 | ≥1990 | ≥25 | 318-342 | 40-43 | -0.12 | -0.6 | 180 | ≥7.5 |

| 40UH | 1.26-1.28 | 12.6-12.8 | 948 | 11.9 | ≥1990 | ≥25 | 302-326 | 38-41 | -0.12 | -0.6 | 180 | ≥7.5 |

| 38UH | 1.22-1.26 | 12.2-12.6 | 925 | 11.6 | ≥1990 | ≥25 | 287-310 | 36-39 | -0.12 | -0.6 | 180 | ≥7.5 |

| 35UH | 1.17-1.22 | 11.7-12.2 | 887 | 11.1 | ≥1990 | ≥25 | 263-287 | 33-36 | -0.12 | -0.6 | 180 | ≥7.5 |

| 33UH | 1.13-1.17 | 11.3-11.7 | 857 | 10.8 | ≥1990 | ≥25 | 247-271 | 31-34 | -0.12 | -0.6 | 180 | ≥7.5 |

| 30UH | 1.08-1.13 | 10.8-11.3 | 819 | 10.3 | ≥1990 | ≥25 | 223-255 | 28-32 | -0.12 | -0.51 | 180 | ≥7.5 |

| 28UH | 1.02-1.08 | 10.2-10.8 | 773 | 9.7 | ≥1990 | ≥25 | 207-231 | 26-29 | -0.12 | -0.51 | 180 | ≥7.5 |

| 42EH | 1.28-1.32 | 12.8-13.2 | 970 | 12.2 | ≥2388 | ≥30 | 318-342 | 40-43 | -0.12 | -0.5 | 200 | ≥7.5 |

| 40EH | 1.25-1.28 | 12.5-12.8 | 948 | 11.9 | ≥2388 | ≥30 | 302-326 | 38-41 | -0.12 | -0.5 | 200 | ≥7.5 |

| 38EH | 1.22-1.26 | 12.2-12.6 | 925 | 11.6 | ≥2388 | ≥30 | 287-310 | 36-39 | -0.12 | -0.5 | 200 | ≥7.5 |

| 35EH | 1.17-1.22 | 11.7-12.2 | 887 | 11.1 | ≥2388 | ≥30 | 263-287 | 33-36 | -0.12 | -0.5 | 200 | ≥7.5 |

| 33EH | 1.13-1.17 | 11.3-11.7 | 857 | 10.8 | ≥2388 | ≥30 | 247-271 | 31-34 | -0.12 | -0.5 | 200 | ≥7.5 |

| 30EH | 1.08-1.13 | 10.8-11.3 | 819 | 10.3 | ≥2388 | ≥30 | 223-255 | 28-32 | -0.12 | -0.51 | 200 | ≥7.5 |

| 28EH | 1.02-1.08 | 10.2-10.8 | 773 | 9.7 | ≥2388 | ≥30 | 207-231 | 26-29 | -0.12 | -0.51 | 200 | ≥7.5 |

| 40AH | 1.25-1.28 | 12.5-12.8 | 948 | 11.9 | ≥2786 | ≥35 | 302-326 | 38-41 | -0.12 | -0.51 | 220 | ≥7.5 |

| 38AH | 1.22-1.26 | 12.2-12.6 | 925 | 11.6 | ≥2786 | ≥35 | 287-310 | 36-39 | -0.12 | -0.51 | 220 | ≥7.5 |

| 35AH | 1.17-1.22 | 11.7-12.2 | 887 | 11.1 | ≥2786 | ≥35 | 263-287 | 33-36 | -0.12 | -0.51 | 220 | ≥7.5 |

| 33AH | 1.13-1.17 | 11.3-11.7 | 857 | 10.8 | ≥2786 | ≥35 | 247-271 | 31-34 | -0.12 | -0.51 | 220 | ≥7.5 |

| 30AH | 1.08-1.13 | 10.8-11.3 | 819 | 10.3 | ≥2786 | ≥35 | 223-255 | 28-32 | -0.12 | -0.51 | 220 | ≥7.5 |

| 28AH | 1.02-1.08 | 10.2-10.8 | 773 | 9.7 | ≥2786 | ≥35 | 199-231 | 25-29 | -0.12 | -0.51 | 220 | ≥7.5 |

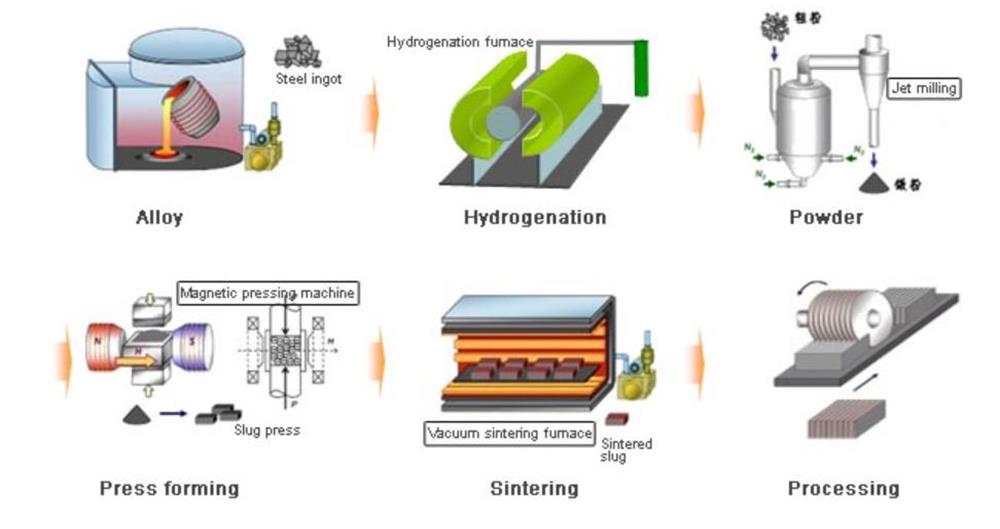

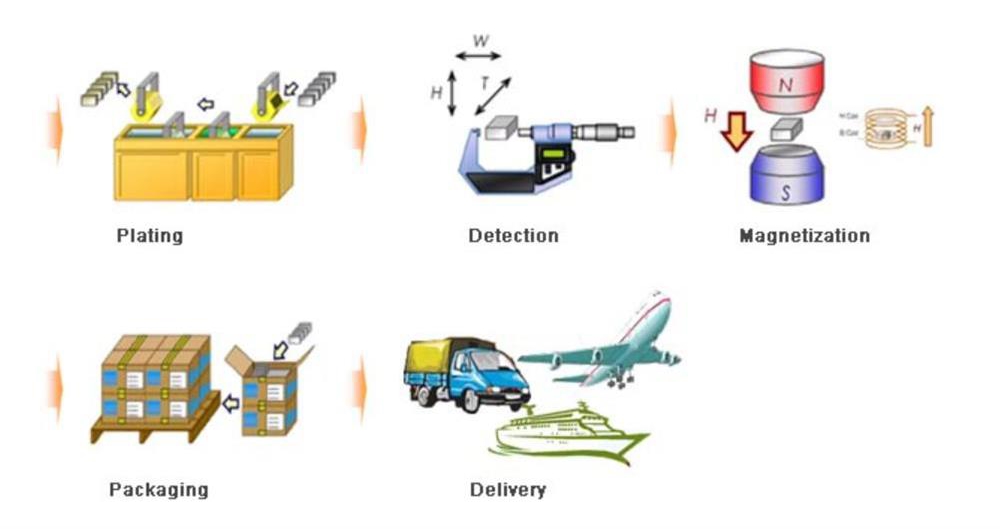

Process Flow Diagram

Dimensional Tolerance

| Squared-shaped products | |||

| Dimensional Range | Dimensional Tolerance | Parallellism | Rectangularity |

| 0.5≤L≤10 | ±0.03 | ±0.03 | <0.3 |

| 10≤L≤50 | ±0.05 | ±0.05 | |

| L>50 | ±0.1 | ±0.1 | |

| Wafer-shaped Products | |||

| Dimensional Range | Circularity | Dimensional Tolerance | Planeness |

| 1≤D≤5 | ±0.02 | ±0.02 | ±0.02 |

| 5≤D≤25 | ±0.03 | ±0.05 | ±0.02 |

| 25≤D≤50 | ±0.05 | ±0.05 | ±0.03 |

| D>50 | ±0.05 | ±0.1 | ±0.1 |

| Ring-shaped Products | |||

| Dimensional Range | Circularity | Dimensional Tolerance | Planeness |

| 1≤d≤3 | ±0.02 | ±0.02 | ±0.02 |

| 3≤d≤5 | ±0.04 | ±0.03 | ±0.02 |

| 5≤d≤15 | ±0.05 | ±0.05 | ±0.03 |

| d>15 | ±0.1 | ±0.05 | ±0.1 |

| Segment-shaped Products | ||

| Geometric Tolerance | Dimensional Range | Dimensional Tolerance |

| Wall Thickness | T≤10 | ±0.04 |

| 10<T≤25 | ±0.05 | |

| Length | L≤10 | ±0.03 |

| 10<L≤25 | ±0.03 | |

| 25<L≤63 | ±0.04 | |

| L>63 | ±0.06 | |

| Chord Length | W≤63 | ±0.05 |

| W>63 | ±0.06 | |

Pulong Magnet has more than 10 years’ experience to deal with the magnets and magnetic products!

Strategic cooperation with China’s No.1 rare earth miner Chinalco!

Contact us today or send us a special request and let us know what you are looking for.

Product detail pictures:

Related Product Guide:

It adheres for the tenet "Honest, industrious, enterprising, innovative" to develop new products and solutions continuously. It regards shoppers, success as its individual success. Let us produce prosperous future hand in hand for Low MOQ for Strong Magnet Hooks - Strong Permanent Neodymium Magnets – Pulong, The product will supply to all over the world, such as: Bahamas, Russia, Puerto Rico, The products has a good reputation with competitive price, unique creation, leading the industry trends. The company insists on the principle of win-win idea, has establishedglobal sales network and after-sales service network.

The after-sale warranty service is timely and thoughtful, encounter problems can be resolved very quickly, we feel reliable and secure.