New Delivery for Neodymium Magnet Properties - Neodymium (NdFeB) Disc Magnets – Pulong Detail:

Product DescriptionStrong Neodymium Magnet Discs & Cylinders

Neodymium (also known as “NdFeb”, “NIB” or “Neo”) disc magnets are the most powerful rare-earth magnets available today. Available in disc and cylinder shapes, Neodymium magnets have magnetic properties that far exceed all other permanent magnet materials. They are high in magnetic strength, moderately priced and able to perform well in ambient temperatures. As a result, they are the most widely-used Rare-Earth magnets for industrial, technical, commercial and consumer applications.

Neodymium Magnets Approximate Pull Information

The approximate pull info listed is for reference only. These values are calculated under the assumption that the magnet will be attached to a flat, ground 1/2″ thick mild steel plate. Coatings, rust, rough surfaces, and certain environmental conditions can significantly reduce the pull force. Please be sure to test the actual pull in your actual application. For critical applications, it is suggested that the pull be de-rated by a factor of 2 or more, depending on the severity of a potential failure.

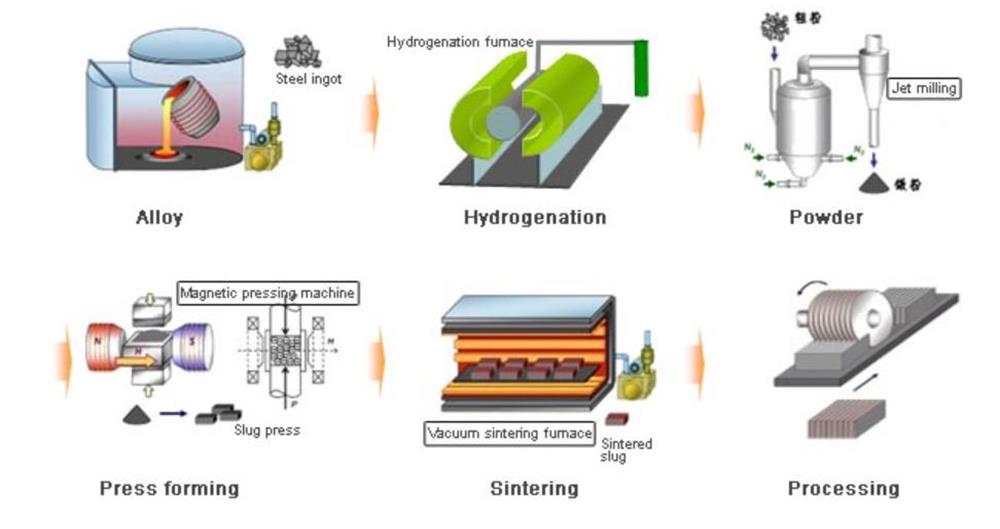

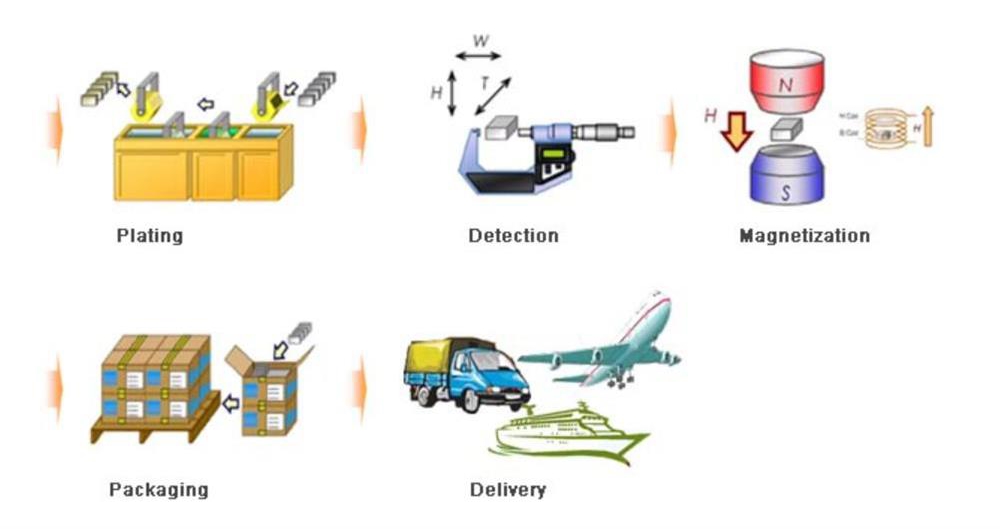

Manufacturing Methods for Neodymium Magnets

Our neodymium discs are sintered for optimal magnetic strength and axially magnetized (the magnetism direction is along the axis of the magnet from the north to the south poles). Common finishing options include uncoated, nickel (Ni-Cu-Ni) and gold (Ni-Cu-Ni-Au) plated coatings.

Standard Measurement Tolerances for NdFeB Magnets

Standard tolerances are +/- 0.005” on both diameter and thickness dimensions.

We never compromise on quality and all our products are performance tested using a computer controlled tensile and compression machine. The system accurately measures the weight a magnet can hold when pulled vertically and the amount of pull a magnet can exert when there is a gap or non-magnetic material between the magnet and the material it is applied to attract. Using the best technology, we make sure our customers always get the correct magnet for their application.

Process Flow Diagram

Product detail pictures:

Related Product Guide:

With reliable good quality system, great standing and perfect consumer support, the series of products and solutions produced by our organization are exported to quite a few countries and regions for New Delivery for Neodymium Magnet Properties - Neodymium (NdFeB) Disc Magnets – Pulong, The product will supply to all over the world, such as: Jamaica, San Francisco, Hungary, During in 11 years, We've participated in more than 20 exhibitions, obtains the highest praise from each customer. Our company has been devoting that "customer first" and committed to helping customers expand their business, so that they become the Big Boss !

The supplier abide the theory of "quality the basic, trust the first and management the advanced" so that they can ensure a reliable product quality and stable customers.