Short Lead Time for Bar Of Magnet - Rubber Coated Neodymium Pot Magnets – Pulong Detail:

Rubber Coated Neodymium Pot Magnets W/Threaded Center Hole

Rubber coated neodymium pot magnets are strong and durable magnetic assemblies with a threaded center hole (internal female thread) and protective rubber coating. Made with N35 neodymium disc magnets attached to a flat steel disc and coated with black isoprene rubber which leaves no marks and prevents surfaces from scratching. The protective rubber coating protects magnets from corrosion or oxidation for sustained use in outdoor environments. It also prevents magnets from chipping easily and provides more slip-resistance than other types of coated or uncoated magnets.

Rubber coated magnets are high in magnetic strength and weatherproof so they are ideal for indoor and outdoor applications where high magnetic strength is required. They are frequently used for holding, mounting and fixing purposes, from mounting lights or fixtures to equipment repair, holding tools and organizing items in warehouses, workstations and outdoor areas.

Product Features

● Strong pull force, waterproof, durable, high traction, corrosion resistant, temperature resistant, magnets do not easily chip.

● Constructed with N35 Neodymium magnet encased in a steel structure & coated with a protective rubber coating.

● Internal Female Thread accommodates standard fasteners & attachments.

● NdFeB Magnets are axially magnetized (through the thickness).

Rubber Coated

Rubber coated neodymium magnets give great durability and high friction. The rubber coating acts as a protection for the Neodymium Magnet against chipping and exposure to liquids. Rubber coated neodymium magnets are used in many holding applications. If you require a specific size, please contact us on use our online custom magnet quote form.

Product Application

These threaded magnetic assemblies are made with the most powerful magnet material available. Each assembly features a neodymium magnet affixed to a flat steel disc and coated with a black protective rubber to prevent surface scratches.

● Attach a hook or knob to position or hold inspection equipment, indicator gauges, lamps, signs, and more

● Ideal for home, office or workshop

● Hundreds of uses sporting, household, industrial and commercial

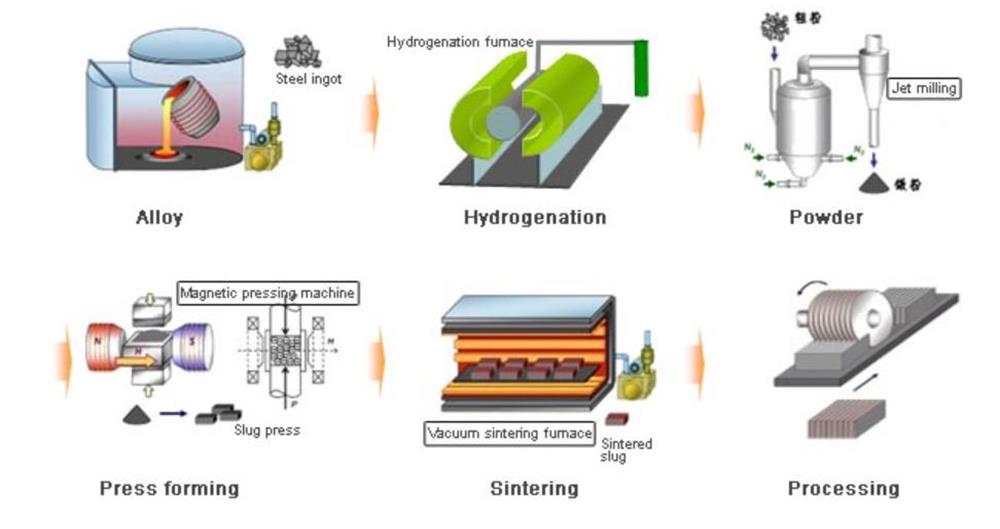

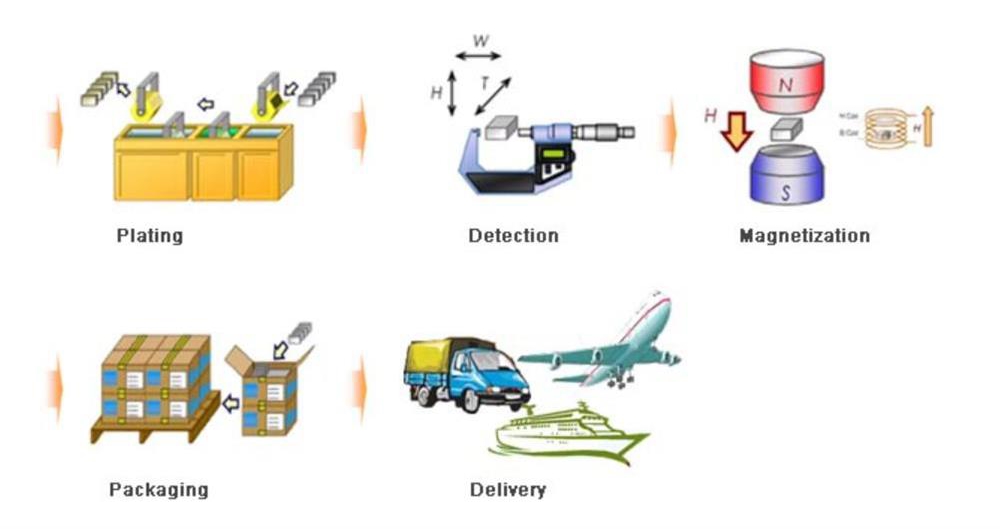

Process Flow Diagram

Product detail pictures:

Related Product Guide:

We rely upon strategic thinking, constant modernisation in all segments, technological advances and of course upon our employees that directly participate in our success for Short Lead Time for Bar Of Magnet - Rubber Coated Neodymium Pot Magnets – Pulong, The product will supply to all over the world, such as: Florence, Sydney, Danish, We have gained a lot of recognition among customers spread all across the world. They trust us and always give repetitive orders. Furthermore, mentioned below are some of the major factors that have played significant role in our tremendous growth in this domain.

The supplier cooperation attitude is very good, encountered various problems, always willing to cooperate with us, to us as the real God.